Experts in high-quality dietary supplement manufacturing

At HealthyLab we combine cutting-edge technology, certified facilities and more than 25 years of experience to turn your ideas into successful products that stand out in the market.

Why choose HealthyLab?

We are your best option for the development and manufacturing of dietary supplements.

Constant innovation

- We develop unique products adapted to market trends.

- Strategic partnerships with global leaders in research and ingredients.

Certified quality

- Manufacturing and distribution permits from COFEPRIS and the FDA.

- Direct link with renowned research centers in northern Mexico.

Capacity and flexibility

- Robust installed capacity for large-scale production.

- Flexibility in dosage forms to meet diverse business needs.

Contract manufacturing service in Mexico and United States

We manufacture from Mexico and ship throughout the Mexican republic and United States with efficient logistics

All Mexico

Complete national coverage from our facilities in Ramos Arizpe, Coahuila. We ship to all states of the Mexican republic.

- Coverage in all 32 states of Mexico

- Fast delivery in northern region (24-48 hours)

- Optimized logistics network nationwide

United States

We export products manufactured under the highest quality standards. We ship throughout the United States with complete documentation.

- Export service to the United States

- International certifications and documentation

- Efficient cross-border logistics

Leaders in supplement manufacturing

With over 25 years of experience, we have manufactured more than 10 million supplements and shipped over 10,000 orders across Mexico.

Experience and trust

Over 25 years helping brands succeed in the market

Certifications and compliance

COFEPRIS and FDA permits for manufacturing and distribution

Innovation and development

Direct partnership with renowned research centers in northern Mexico

Comprehensive services

We offer complete solutions for the development and manufacturing of your products.

Development and formulation

Customized according to your needs. Our team of experts develops unique formulas adapted to your target market.

Manufacturing

With high GMP standards. Our facility has the technology and processes necessary to guarantee the highest quality products.

Quality control

Microbiological tests and physicochemical analysis. Our laboratory performs comprehensive testing to ensure the safety and efficacy of each product.

Logistics and distribution

Nationwide and international with optimized costs. We have a robust logistics system with more than 10,000 annual shipments in Mexico and constant international expansion.

Download our commercial presentation

Learn more about our services, capabilities and success stories in a complete PDF

Dosage forms

Wide variety of dosage forms to meet diverse business needs.

Tablets and capsules

Standard and specialized (Capsules 0 and 00). Production capacity of 1,392,000 tablets/day and 1,000,000 capsules/day.

Softgel capsules

High demand in premium supplements. Production capacity of 1,000,000 softgel capsules/day.

Powders

In sachet (5-25 g) and bottle (100-500 g). Production capacity of 21,600 sachets per shift.

Gummies

Innovative and attractive format for dietary supplementation. Our precision manufacturing process guarantees high-quality gummies with exact dosing. Production capacity of 150 kg/h.

Our facilities

State-of-the-art facilities certified under the strictest quality standards

Certified clean rooms

State-of-the-art facilities with environmental control

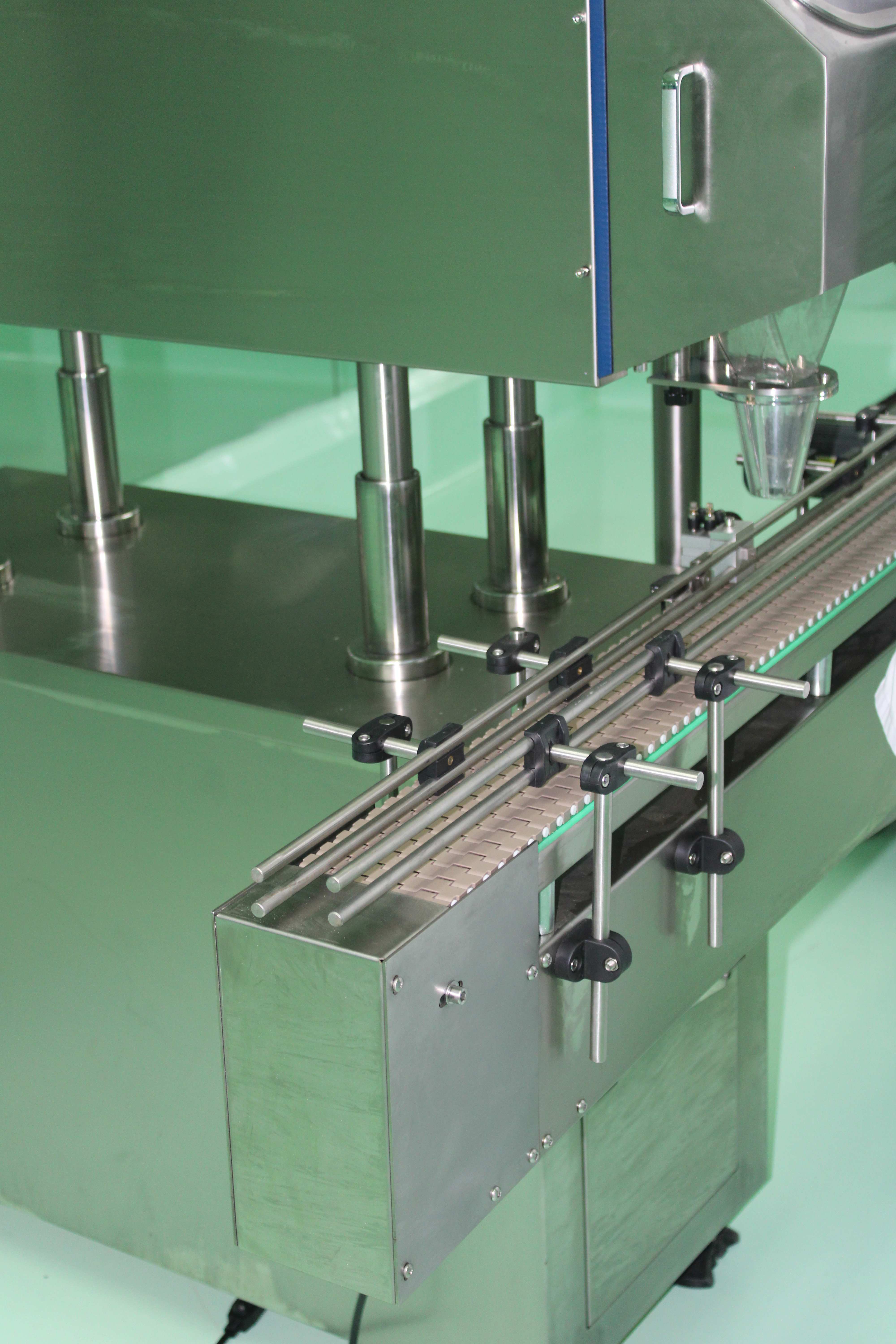

Automated production lines

Cutting-edge technology for efficiency and precision

In-line quality control

Automatic verification systems at every stage

Controlled processes

Highly trained personnel in every process

Specialized equipment

Latest generation machinery for maximum efficiency

Professional operation

Certified technicians monitoring every batch

Automated packaging

Precision temperature control and sealing

Continuous production flow

Efficient and safe transportation systems

Precise dosing

Automatic filling with millimeter accuracy

High production capacity

Scalable volumes according to your needs

Precision in every detail

Exhaustive control in capsule production

Continuous monitoring

Constant supervision to ensure quality

GMP certification

Facilities that comply with good manufacturing practices

Controlled areas

Environments with temperature, humidity and particle control

Modern equipment

Latest generation machinery for maximum efficiency

How to start your project?

A simple and efficient process to take your idea to market.

Initial contact

Share your idea or need with us. We'll discuss your project goals and requirements.

Requirement definition

We specify the exact product, dosage form, quantities and timelines.

Quotation

We present a detailed technical and economic proposal for your approval.

Formulation

Our experts develop the perfect formula for your product.

Validation

Quality testing and regulatory compliance before full-scale production.

Manufacturing

Production under GMP standards with rigorous quality control.

Discover HealthyLab

Explore our manufacturing process and the facilities where we transform your vision into products of excellence

How is a supplement made?

Our Facilities

Contact us

We are ready to help you develop your next successful product.

Frequently asked questions about supplement manufacturing

Answers to the most common questions about our contract manufacturing service

What is dietary supplement contract manufacturing?

▼

Dietary supplement contract manufacturing is a service where we produce your products under your brand. It includes everything from developing custom formulas to final packaging, allowing you to launch your own supplement line without investing in specialized facilities or equipment.

What is the process to start contract manufacturing with HealthyLab?

▼

The process is simple and has 6 stages:

- Initial contact: Share your idea or need with us

- Requirement definition: We specify the exact product

- Quotation: We present technical and economic proposal

- Formulation: We develop the perfect formula

- Validation: Quality testing and regulatory compliance

- Manufacturing: Production under GMP standards

What certifications does HealthyLab have?

▼

We have the most important certifications in the industry: COFEPRIS (Federal Commission for Protection against Sanitary Risks in Mexico) and FDA (Food and Drug Administration), which certify us to manufacture and distribute dietary supplements in Mexico and the United States. Additionally, we follow GMP (Good Manufacturing Practices) standards that ensure the quality and safety of all our products.

What is the minimum production volume?

▼

Minimum volumes vary depending on the dosage form and product complexity. Generally, we handle batches from 5,000 units for tablets and capsules. For powders and gummies, minimums may be different. We invite you to contact us to discuss your specific project and find the most suitable option for your needs.

How long does the development and manufacturing process take?

▼

Times vary depending on project complexity:

- Formula development: 2-4 weeks

- Validation and quality testing: 1-2 weeks

- Initial production: 2-3 weeks

In total, the process can take 6-10 weeks from initial contact to finished product, although we can expedite times for urgent projects.